At Optima Chemical, our first words to you are typically ‘Welcome, how can we help you’. If there is one thing that epitomises Optima, it is a commitment to truly serve our customers and it runs deep, through every level of the organisation. We believe it is the key to our growth from the company that offered a single product almost 30 years ago to the one we are today, a full-service chemical company with the infrastructure to take ideas through to delivered products and solutions.

Optima has an engineering skill-set that enables us to manufacture high-energy and high-hazard, sensitive chemistry safely at scale at two US-based manufacturing plants, where we make products for our contract partners as well as own. Our laboratories are run by a team that offers technical support to our contract manufacturing partners as well as analytical development, route development and scale-up for other customers, be it for custom-made products or some short-term use of our facilities. Underpinning all of this is a culture of safety, service and flexibility.

The single product that we first offered 30 years ago was sodium tetraphenyl borate; we handled magnesium and made our own Grignards. We still do this today, but the business has evolved and grown. We now handle many metals, make many organometallics and have our own product lines that stem from this technology platform. One of our key products is used as an intermediate for in a launched new drug and 2018 saw Optima rise to the challenge of a twelve-fold increase in its manufacturing throughput. We delivered this within a year, under the pressure of actual production for the customer.

On the contract manufacturing side, 2019 has seen us rise to the challenge of helping a new blue-chip customer to launch of their latest technology to the consumer market. Working closely with our customer, we took the project from process development through to commercial production within ten months, with significant investment from Optima in order to make it happen.

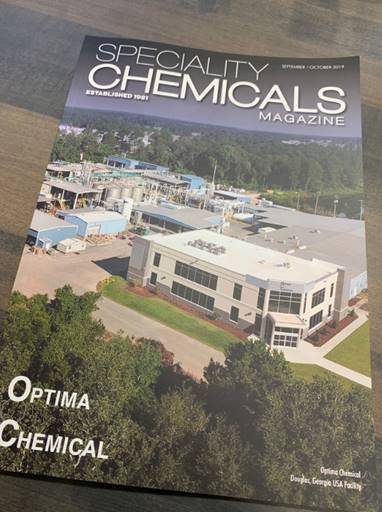

The significant organic growth we have experienced over the last few years has been fueled by investment in our plant at Douglas, Georgia, and the acquisition of additional plant at Belle, West Virginia, bought from DuPont at the end of 2015. Our overall reactor capacity now stands at approximately 100,000 gallons (380 m3). The expectation is for further significant growth over the next few years.

In parallel to the plant investment projects, we designed and built a new headquarters in 2019. Based at the Douglas site, the new building is two-story, 16,000 ft2 (1,486 m2) and designed to be a collaborative space that is an efficient working environment for teams. It goes without saying that we delivered this project in less than 12 months too.