Adsorbents are materials that have the capacity to hold molecules of gases, liquids, or dissolved substances on their surface. This characteristic makes them vital in various industries, including environmental management, pharmaceuticals, and chemical processing. The process of adsorption involves the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid to a surface, creating a film of the adsorbate on the surface of the adsorbent. This process is widely used for purification, separation, and decontamination processes.

Recent advancements in adsorbent technology focus on enhancing the efficiency and selectivity of adsorbents. Researchers are developing novel materials such as metal-organic frameworks (MOFs) and carbon nanotubes, which offer higher surface areas and tunable pore structures. These innovations hold promise for more effective environmental cleanup, improved industrial processes, and the development of new pharmaceutical applications.

Types of Adsorbents

- Activated Carbon is one of the most common adsorbents used for water and air purification. Its high surface area and porous structure make it highly effective in removing contaminants.

- Silica gel is a highly porous form of silicon dioxide (SiO2). It is commonly used as a desiccant to control humidity and in chromatography for separation purposes.

- Zeolites are crystalline aluminosilicates known for their uniform pore size and high surface area. They are extensively used in gas separation and as catalysts in chemical reactions.

- Activated alumina is a form of aluminum oxide used in water purification and as a catalyst in various chemical processes. It is particularly effective in adsorbing fluoride and arsenic.

- Natural clays, such as bentonite and kaolin, are used as adsorbents in a variety of applications, including oil refining and wastewater treatment.

Applications of Adsorbents

- Water Treatment – Adsorbents play a crucial role in the removal of pollutants from water. Activated carbon, for instance, is widely used in both municipal and industrial water treatment facilities to remove organic compounds and chlorine.

- Air Purification – In air filtration systems, adsorbents like activated carbon are used to remove volatile organic compounds (VOCs) and other pollutants from the air, improving indoor air quality.

- Chemical Processing – In the chemical industry, adsorbents are used to separate and purify products. Zeolites are particularly valued for their ability to catalyze reactions and facilitate the separation of hydrocarbons in petroleum refining.

- Pharmaceuticals – Adsorbents are used in the pharmaceutical industry for the purification of active pharmaceutical ingredients (APIs) and the removal of impurities during drug manufacturing.

- Environmental Cleanup – Adsorbents are critical in environmental remediation efforts. They are used to clean up oil spills, remove heavy metals from soil, and treat contaminated groundwater.

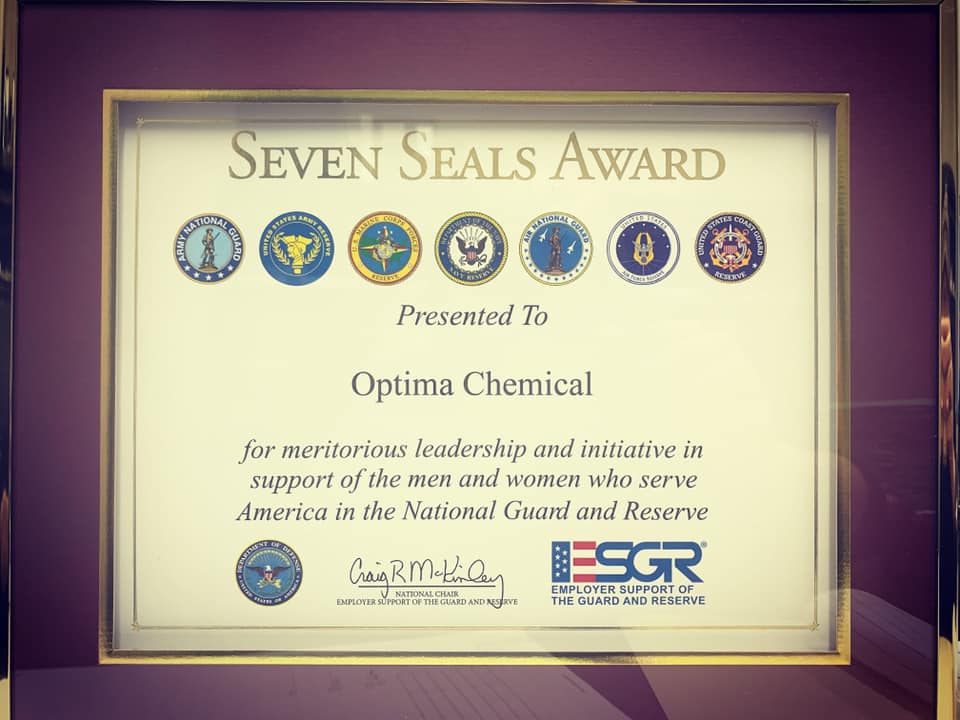

Optima Chemical has growing portfolio of customers in the adsorbents market. Built on a history manufacturing and modifying Zeolite materials, we both help customers develop and scale-up their new technologies as well custom manufacture materials. Our clients range from global blue-chip companies to cutting edge start-ups. Our flexibility to handle a broad range of chemistries from Alumininates and Silicates through to more complex organometallic and polymer chemistry has enabled us to assist our clients across all application areas.

Contact us today and see how Optima Chemical can help you in the development of your new Adsorbent technology.